numéro d'article:

PEEK-NA-LCF30Paiement:

T/T or L/C (other payment ways also can be diorigine du produit:

Xiamen, ChinaCouleur:

Original color (also can be customized)port d'expédition:

Xiamen, ChinaPEEK-LCF

Polyether ether ketone (abbreviated PEEK) not only has excellent mechanical, heat and chemical resistance properties, and low friction coefficient, good bearing meshing, is another kind of good self-lubricating material after polytetrafluoroethylene (PTFE), in the bearing capacity and wear resistance than PTFE performance is better, In no lubrication, low speed and high load, high temperature, humidity, pollution, corrosion and other harsh environment is especially suitable. On this basis, the addition of carbon fiber not only enhances its mechanical properties, its friction performance has important influence.

At room temperature, the tensile strength of 30% carbon fiber reinforced PEEK composite doubled, and reached three times at 150℃. At the same time, the impact strength, bending strength and modulus of the reinforced composite were also greatly improved, the elongation was sharply reduced, and the thermal deformation temperature could exceed 300℃. The impact energy absorption rate of the composite directly affects the impact performance of the composite. The carbon fiber reinforced PEEK composite shows a specific energy absorption capacity of up to 180kJ/kg.

The reinforced effect of carbon fiber can also resist the thermal softening of PEEK and form a transfer film with very high strength to a certain extent, which can effectively protect the contact area. Therefore, the friction coefficient and specific wear rate of carbon fiber reinforced PEEK composite are significantly lower than that of pure PEEK. Under the same experimental conditions, the friction and wear resistance of carbon fiber reinforced PEEK composites is obviously better than that of glass fiber PEEK composites, and the improvement effect of carbon fiber on the wear resistance of materials is more than 5 times that of glass fiber with the same dosage. Carbon fiber reinforced PEEK composite material is used in parts manufacturing, which can effectively avoid the surface cracks of metal or ceramic materials, and its excellent tribological properties even exceed that of ultra-high molar mass polyethylene.

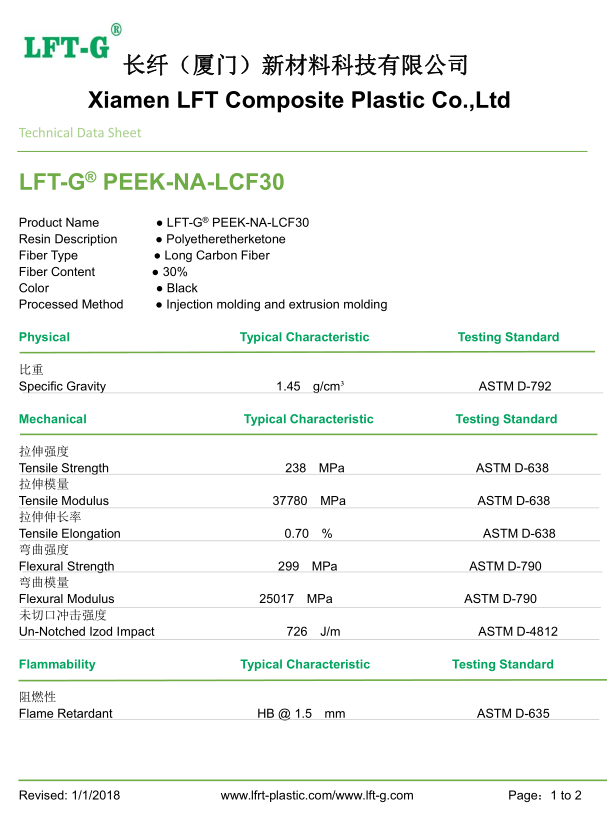

TDS

Application

Long carbon fiber reinforced PEEK is mainly applied in the following four areas:

1. Electronic and electrical appliances

PEEK can maintain good electrical insulation in the harsh environment such as high temperature, high pressure and high humidity, and has the characteristics of non-deformation in a wide temperature range, so it is used as an ideal electrical insulation material in the field of electronic and electrical appliances. The mechanical properties, chemical corrosion resistance, radiation resistance and high temperature resistance of polyether ether ketone reinforced by carbon fiber have been further improved, and its application fields have been further expanded.

2. Aerospace

Polyether ether ketone PEEK has the advantages of low density and good workability, so it is easy to be directly processed into high-demand parts, and carbon fiber reinforced polyether ether ketone composite material further enhances the overall performance of polyether ether ketone, so it is increasingly used in aircraft manufacturing. The fairing on Boeing's 757-200 series aircraft, for example, is made from carbon-fiber reinforced PEEK. In addition, Gereedschappen Fabrick of Amsterdam, the Netherlands, used a 30% carbon fiber reinforced PEEK composite to build a larger component and demonstrated that its mechanical properties could be used in aircraft balancing devices.

3. Automotive

Automobile energy consumption is closely related to vehicle weight. Automobile lightweight can not only reduce fuel consumption and exhaust emissions, but also improve power performance and safety, which is an effective way to save energy. In addition to the lightweight design of the structure, the use of lightweight materials is a more direct method. With its advantages of low density, good performance and convenient technology, carbon fiber reinforced polyether ether ketone composites are more and more frequently used in the automobile industry, and show great potential of replacing steel with plastic. For example, Robert Bosch GmbH uses carbon fiber reinforced PEEK instead of metal as a feature of ABS. The lighter composite part reduces moment of inertia, which minimizes reaction times, greatly enhances the overall system's reactivity, and reduces costs compared to previously used metal parts.

4. Healthcare

Currently available medical polymer materials are polytetrafluoroethylene, polylactic acid, silicone rubber and dozens of kinds, but from the point of view of biomedicine, these materials are not ideal, in the use of some side effects, and PEEK resin because of its non-toxic, light weight, abrasion resistance and other advantages, is the material closest to the human skeleton, can be organically combined with the body, Therefore, polyether ether ketone resin and its composite materials have been deeply studied and applied in spine and joint as orthopedic implants in recent years. Compared with ultrahigh molecular weight polyethylene (UHMPE), carbon fiber reinforced polyether ether ketone has higher wear resistance and better biocompatibility, and is an ideal material for future acetabulum prosthesis. By comparing the cytotoxicity of carbon fiber reinforced polyether ether ketone with titanium alloy, it was found that the two materials have similar cytocompatibility. Carbon fiber reinforced polyether ether ketone composites can be used as alternative materials for orthopedic fixation devices in the future. The existing typical applications in China are the medical instruments such as carbon fiber reinforced PEEK bone surgical fixation bracket and sight bracket adopted by Wuxi Zhishang New Material Technology Co., LTD., which perform well in strength, corrosion resistance, wear resistance and moisture and heat resistance, and are expected to be applied in more high-end medical instruments.

Xiamen LFT plastique composite Co., Ltd.