nouveau blog

Dans le domaine en constante évolution de la science des matériaux, en fibre de carbone est devenu une pierre angulaire dans de nombreux secteurs haut de gamme en raison de ses performances exceptionnelles. Des équipements aérospatiaux de haute précision aux innovations légères dans la fabrication automobile et même les améliorations des performances dans les équipements sportifs, la fibre de carbone est partout. Ces dernières années, l'industrie nationale des fibres de carbone a fait des progrès remarquables et a réalisé des réalisations importantes. Cependant, par rapport à la fibre de carbone importée, il existe encore des lacunes de performances qui ne peuvent pas être ignorées. Aujourd'hui, faisons-nous dans les différences entre les deux.

2. Comparaison des paramètres de performance: Fibre de carbone domestique et importé

Selon les données accessibles au public, dans le secteur des fibres de carbone haut de gamme, les fibres de carbone importées maintiennent toujours un avantage d'attaque dans la résistance à la traction et le module de traction en raison des avantages technologiques de longue date qu'ils ont accumulés. Toray, un leader mondial de l'industrie des fibres de carbone, produit certains modèles de fibre de carbone avec des performances exceptionnelles. La résistance à la traction de ces fibres peut dépasser 7000 MPa , et le module de traction est supérieur à 300 GPa . Ces données indiquent que ces matériaux en fibre de carbone peuvent résister à une tension énorme sans se casser et posséder une rigidité extrêmement élevée.

Les produits domestiques en fibre de carbone haut de gamme ont fait des percées importantes ces dernières années, réalisant des progrès remarquables. Cependant, en moyenne, leur résistance à la traction varie entre 6000 et 6500 MPa , et le module de traction se situe entre 280 et 300 GPa . Bien qu'il y ait encore un certain écart par rapport aux produits importés, les fibres de carbone intérieures continuent de faire des progrès, avec une augmentation continue de l'investissement en R&D et des améliorations progressives de la technologie.

Dans les secteurs du milieu à la fin, la fibre de carbone domestique a montré une forte compétitivité. Ses performances sont suffisantes pour répondre à la plupart des besoins d'application conventionnels, tels que dans les produits industriels et équipements sportifs généraux . De plus, la fibre de carbone domestique est plus rentable, ce qui permet à de nombreuses petites et moyennes entreprises d'adopter des matériaux en fibre de carbone à un coût inférieur , favorisant ainsi l'application plus large de la fibre de carbone dans diverses industries.

3. Différences de performance dans les applications pratiques

dans l'industrie aérospatiale, où les exigences de performance des matériaux sont presque rigoureuses, la fibre de carbone importée a longtemps occupé une position dominante en raison de ses performances stables et exceptionnelles. Les composants structurels critiques comme les ailes d'avion et les fuselages bénéficient de l'utilisation de la fibre de carbone importée pour assurer la sécurité et l'efficacité énergétique de l'avion. Prendre des fabricants d'aéronefs internationaux renommés tels que Boeing et Airbus À titre d'exemples, ils utilisent largement les matériaux de fibre de carbone importés haut de gamme dans leur production d'avion. Ces avions doivent fonctionner dans diverses conditions météorologiques complexes et états de vol, ce qui exige une fiabilité et une stabilité extrêmement élevées des matériaux. La fibre de carbone importée est en mesure de répondre à ces exigences strictes.

Cependant, dans le secteur des équipements sportifs , la fibre de carbone nationale a déjà trouvé une application généralisée. Dans Bicycle Manufacturing , les vélos de fibre de carbone domestiques ont gagné en popularité parmi les amateurs de cyclisme en raison de leur plus grande rentabilité. Bien qu'ils puissent être légèrement à la traîne des produits importés en termes de performances, les vélos intérieurs en fibre de carbone ont obtenu un bon équilibre en termes LETUILLE, RIGIDICE ET CONFORT grâce à des processus de conception et de fabrication optimisés.

Dans la fabrication de cannes à pêche, les tiges de fibre de carbone domestiques se produisent également parfaitement. Leur excellente ténacité et force leur permettent de répondre aux besoins des amateurs de pêche dans divers environnements d'eau et scénarios de pêche.

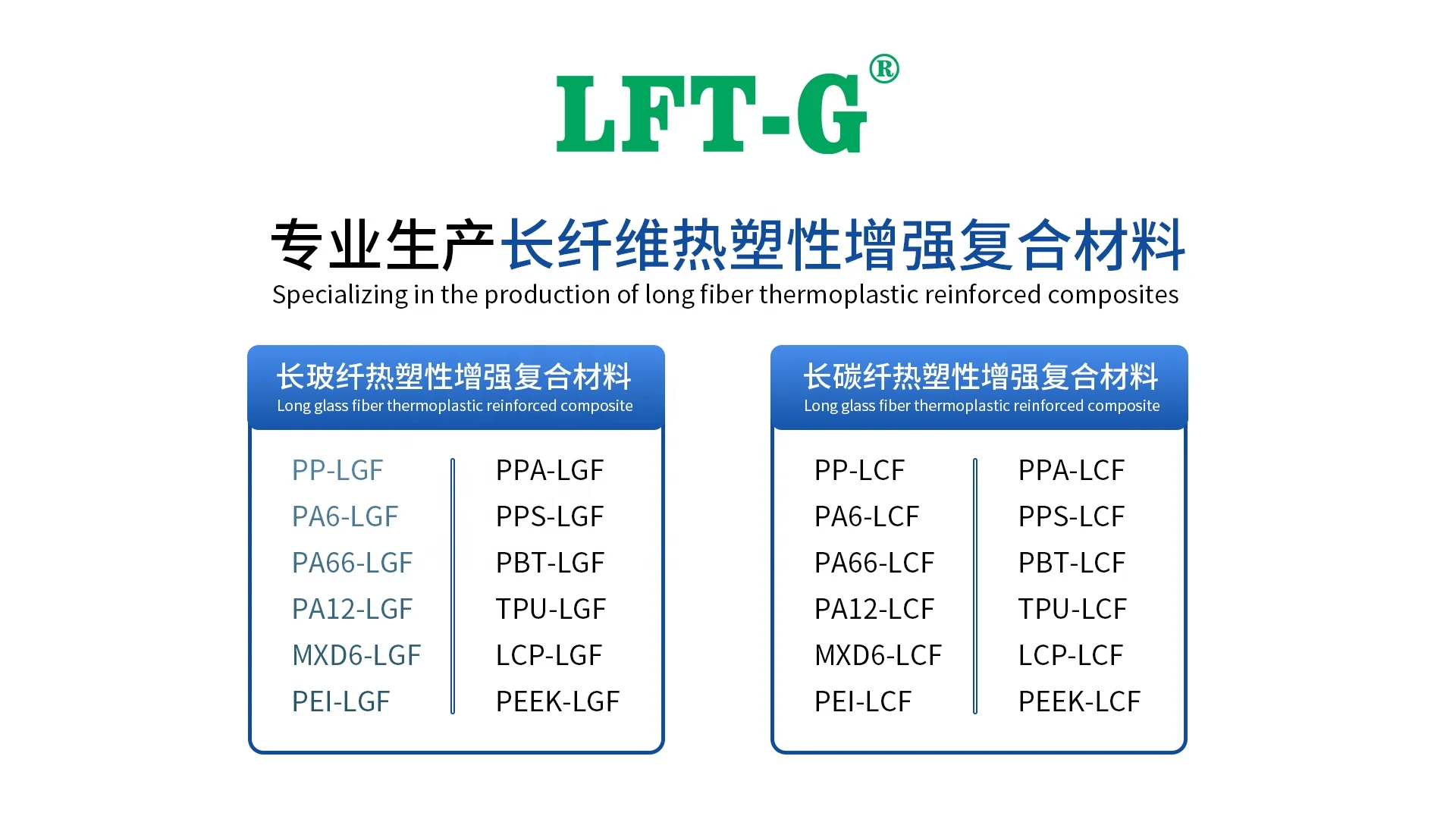

XIAMEN LFT-G OFFRES Spécifications en fibre de carbone importées et produites au niveau national pour nos matériaux composites en fibre de carbone. Nous vous offrons une gamme d'options pour répondre au mieux aux besoins de votre projet. Pour votre commodité, nous sommes heureux de fournir des données de test de laboratoire pour vous aider à prendre une décision éclairée. Veuillez nous contacter pour des informations plus détaillées et pour recevoir les données de test.