numéro d'article:

MXD6-NA-LGF30Paiement:

T/T or L/C (other payment ways also can be diorigine du produit:

Xiamen, ChinaCouleur:

Original color (also can be customized)port d'expédition:

Xiamen, ChinaMXD6 introduction

Polyhexanediyl m-dimethylamine, referred to in English as mxd6, generally referred to as "nylon mxd6", the resin has higher mechanical strength and modulus than other engineering plastics, but also a special high barrier nylon material.

Nylon mxd6 is one of aromatic and aliphatic polyacyl limbs, which is produced by m-phenylenedimethylamine and adipic acid.

In industrial production, in order to make the raw materials economical and easy to obtain, often mixed xylene as raw materials, first made of m-phenylene dimethylamine content higher than 70% of mixed benzene dimethylamine, and then with adipic acid to generate salt, in the presence of a small amount of stabilizer adipic acid and appropriate amount of water for the pressure condensation reaction, the resulting polymer is a hybrid.

Although the barrier property of mxd6 is a little less than that of pvdc and evoh, its barrier property is not affected by temperature and humidity, which is especially suitable for high temperature and humid occasions. In today's barrier packaging and the general trend to replace steel with plastic, nylon mxd6 has become one of the striking new plastic varieties.

Advantages

1、Maintain high strength and rigidity in a wide temperature range

2、High heat deflection temperature, small coefficient of thermal expansion

3、Low water absorption, small size change after water absorption, less mechanical strength reduction

4、Small shrinkage rate of molding, suitable for precision molding process

5、Excellent paintability, especially suitable for surface painting under high temperature

6、Excellent barrier to oxygen, carbon dioxide and other gases

Long glass fiber compounds

Long glass fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long glass fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanical properties of engineering polymers, and increase the durability by forming long fibers to form a long-fiber-reinforced internal skeleton network.

Application

MXD6 can be filled with glass fibers to create a glass fiber reinforced material containing 20-60% glass fiber with exceptional strength and stiffness. Even when filled with high levels of glass fiber, its smooth, resin-rich surface creates a high gloss surface as without glass fiber, making it ideal for painting, metal coating or creating naturally reflective housings.

1、High fluidity for thin wall

It is a very high flowing resin that can easily fill thin walls as thin as 0.5 mm in thickness even when the glass fiber content is as high as 60%.

2、Excellent surface finish

The resin-rich perfect surface has a highly polished appearance, even with a high glass fiber content.

3、Very high strength and stiffness

With 50-60% glass fiber reinforcement, MXD6 has tensile and flexural strengths similar to many cast metals

and alloys.

4、Good dimensional stability

At ambient temperature, the coefficient of linear expansion (CLTE) of MXD6 glass fiber composite is similar to that of many cast metals and alloys. It is highly reproducible due to low shrinkage and the ability to maintain tight tolerances (length tolerances can be as low as ± 0.05% if properly formed).

MXD6 replaces metal in the production of high-quality structural parts for automobiles, electronics, and appliances

In automotive parts, many occasions require material products with high mechanical strength and good oil resistance, and can be used in the range of 120 ~ 160 ℃ for a long time. Glass fiber reinforced MXD6 has a heat resistance of up to 225°C and high strength retention at high temperatures, and can be used in cylinder blocks, cylinder heads, pistons, timing gears, etc. of automobile engines.

MXD6/PPO alloy has the properties of high temperature resistance, high strength, oil resistance, wear resistance, good dimensional stability, etc. It can be used for vertical outer panels of automobile bodies, front and rear fenders, wheel covers and curved parts that can hardly be formed by stamping with steel plates and automobile chassis.

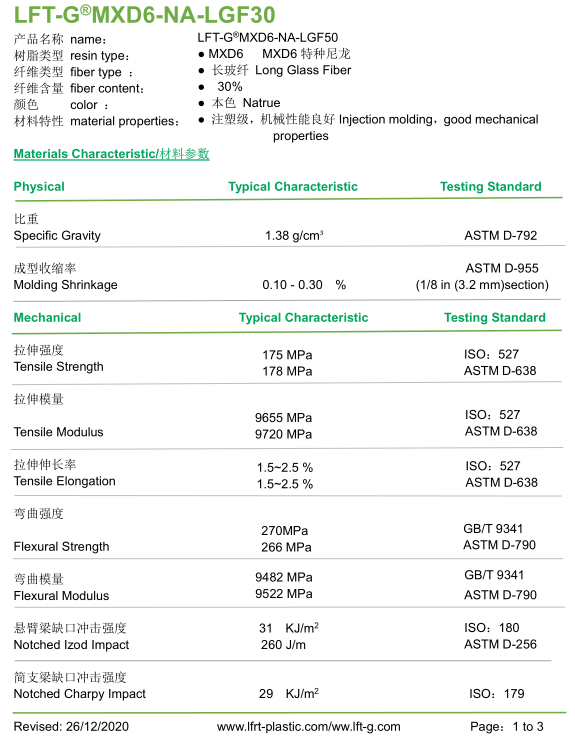

TDS foryour reference

Certifications

Quality Management System ISO9001/1949 Certification

Certificat national d'accréditation de laboratoire

Entreprise d'innovation en matière de plastiques modifiés

Certificat honorifique

Tests REACH et ROHS sur les métaux lourds

Xiamen LFT plastique composite Co., Ltd.

Xiamen LFT composite plastic Co., Ltd est une entreprise de marque qui se concentre sur LFT & LFRT. Série de fibres de verre longues (LGF) et série de fibres de carbone longues (LCF). Le LFT thermoplastique de la société peut être utilisé pour le moulage par injection et l'extrusion LFT-G, et peut également être utilisé pour le moulage LFT-D. Il peut être produit selon les exigences du client : 5~25mm de longueur. Les thermoplastiques renforcés par infiltration continue de la société ont passé la certification du système ISO9001 et 16949, et les produits ont obtenu de nombreuses marques et brevets nationaux.