Fiber reinforced composite materials such as glass fiber, carbon fiber and glass fiber reinforced plastic have been widely used as building materials, mainly in structural reinforcement, glass fiber reinforced plastic tile and glass fiber reinforced pultrusion profiles.

According to a report released by research firm MarketsandMarkets, the global construction composites market is expected to reach $8.98 billion by 2026, with a CAGR of 6.00% over the forecast period. The construction field has become the most potential fiber composite application market after the automobile, aerospace.

Now, let's take a look at some of the world's most famous buildings using fiber-reinforced composites.

1. Eu Prosecutor's Office building

The Dutch TGM construction company, Indupol, Linkvision, BuFA and Solico, through close and successful cooperation, successfully realized the unique design and shape of the facade of the EU Prosecutor's Office building, infusing innovative composite material application technology into the construction industry.

The composite parts were manufactured by Indupol and moulded with a hand paste process to obtain specific shapes and sizes using resin from Liansi and Bufa (delivered by distributor Euroresins). After the molding, the finished product is treated and coated with white topcoat before being transported to the installation site. The installation of the product requires only a small amount of scaffolding, which is lifted by a crane and mounted onto the building.

2. The Building of Newtown Primary School, Calcutta, India

Designer Abin Chaudhuri of Abin Design Studio has created a unique landmark for Newtown Primary School in Kolkata, India. From a distance, each facade looks like an intricate Rubik's Cube® with letters and mathematical symbols. The letters and symbols create a kind of custom template for the facade. These structures provide children with a graphical but interesting aesthetic experience.

Due to the need for a wide variety of complex shapes that are durable and lightweight, the team created 488 panels measuring 3.2 x 3.2 meters from glass fiber-reinforced composites, each consisting of 13 different combinations of symbols. After experimenting with several different composites and non-composites, the team determined that a fiberglass felt-reinforced polypropylene system best met its needs. Each plate weighs only 154 pounds. A grid-like frame made of steel is matched with FRP plates, and Z-shaped steel is embedded in the plates and fastened to the building. Structural concrete slabs protrude from the surface of the building to ensure that a precise number of slabs can be installed on all surfaces of the facade. This makes the panels easier to install from behind and ensures better lighting. The panels are mounted in different directions, giving the facade a random effect. When completed, this facade wraps around a 27,000 square foot building.

3. San Francisco Museum of Modern Art (SFMOMA)

Kreysler & Associates designed 700 Rainscreen fiber-reinforced composite panels for the east facade of the San Francisco Museum of Modern Art (SFMOMA). These FRP panels cover the 10-storey building and are waterproof. These FRP panels are attached to an aluminum frame, creating a horizontal rippling texture like the waters of San Francisco Bay. According to Bill Kreysler, president of Kreysler & Associates, the SFMOMA extension is the largest application of fiber-reinforced composite cladding for a multistory building in North America.

The FRP plates are made of recycled foamed polystyrene (EPS) foam molds and are first ground into rough shape by a CNC wire machine and then used for the final double-curved surface with a five-axis CNC router mechanism. No two boards are the same, and most are 5.5 feet wide and 6 to 30 feet long. Its surface thickness is only 3/16 of an inch.

4. The Apple Headquarters Building

Apple's new $5 billion headquarters in Cupertino, California, will feature a 64,250 square meter roof made by Dubai's First Composite Technologies.

It's the largest freestanding carbon fiber roof ever built. The circular roof consists of 44 panels of the same radius, each 70 feet long and 11 feet wide, connected to a small central hub. Assembled and tested in the Dubai desert before being shipped to Cupertino, Calif., it weighs 80 tons and is more than 140 feet in diameter. By comparison, the Boeing 787 has a takeoff weight of less than 30 tons and a wingspan of 197 feet.

5. Grand Mosque in Mecca

This is another spectacular creation by Dubai's First Composite Technology (PCT), which has built one of the world's largest sliding domes at Mecca's Grand Mosque. It will be 36 meters in diameter, driven by a moving system, with a lower dome and a double layer of upper cladding. Glass fiber reinforced polymer (GFRP) panels are used to cover the structural steel frame of the roof, according to Djibril Waimer, marketing and events coordinator at PCT. The frame, which is supported on four electric wheel drives, can slide to the side so that the courtyard can be open air, providing natural ventilation to the mosque.

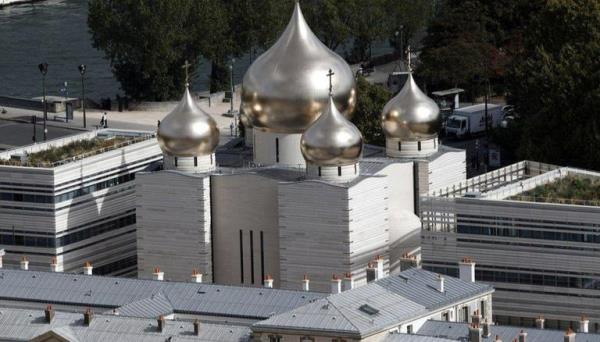

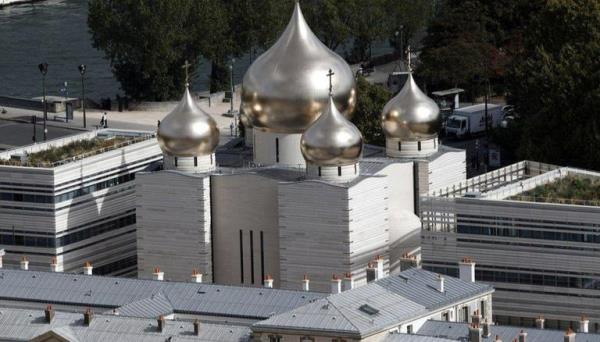

6. Russian Orthodox Cathedral, Paris

Sicomin, a company that formulates high-performance epoxy resin systems, supplied five gilded domes of the Russian Orthodox Cathedral in Paris with a complete set of composite materials that make both molds and components. Sicomin supplied Decision, Carboman Group, Switzerland, with materials for the cupola moulds, using Sicomin's SR8100 / SD7820 high efficiency 120°C Tg epoxy resin filling system for a set of glass fibre multi-axial fabric and basa wood reinforced moulds.

The sheet for the dome itself is produced at Multiplast's facility in Vanna, France using a Sicomin SR8100 / SD4772 epoxy perfusing system and a specially developed fiberglass reinforced material layup. By combining its heavyweight quadaxial branded fabric QX1180 and 500 gsm machine fabric. The use of Sicomin's composite solution for the dome had a number of advantages for the project. Lightweight roofs can be installed quickly and reduce the static load on the structure. Another benefit is that the off-line production and decoration of the roof can be carried out under controlled conditions and the production process is not affected by the weather. Sicomin carried out extensive DSC tests in the laboratory to optimize the post-curing process to ensure the stability of the finished parts before craftsmen plated 86,000 pieces of real gold leaf on the surface of the 640 square meter dome.

7. Ecocapsule

En utilisant des matériaux composites légers, l'équipe slovène a conçu l'Ecocapsule, une minuscule maison capsule de 4,57 mètres de long et 2,13 mètres de large avec une surface utilisable de seulement 6,5 mètres carrés. L'équipe a utilisé de la fibre de verre et de la résine de polyester pour créer les trois composants principaux de la capsule (bas, demi-arc gauche et demi-arc droit), ainsi que les portes, les fenêtres et d'autres composants intérieurs. À l'aide d'un processus de fabrication infusé sous vide, un tissu en fibre de verre et une résine de polyester sont superposés sur la structure en aluminium pour créer la capsule légère.

Une fois le cadre terminé, le reste des composants (y compris l'électricité, le système d'eau, le système de chauffage par le sol, l'intérieur, etc.) sont installés manuellement. Les armoires à l'intérieur sont constituées de panneaux en nid d'abeille légers. Une fois terminée, la capsule ne pèsera que 1,18 tonne.

8. John Madejski Courtyard Pavilion, The Victoria and Albert Museum (V&A), Londres

Les architectes expérimentaux Achim Menges et Moritz Dorstelmann ont travaillé avec l'ingénieur en structure Jan Knippers et l'ingénieur climatique Thomas Auer pour développer des kiosques en fibre de carbone tissés par robot. Le pavillon est maintenant exposé dans la cour de John Madejski au Victoria and Albert Museum (V&A) à Londres. La conception de chaque composant du pavillon est basée sur la structure de l'aile avant du scarabée - connue sous le nom de "gaine d'aile". La structure de 200 mètres carrés est soutenue par des supports en forme d'entonnoir, dont chacun est constitué d'une seule section de résine recouverte de fibres et pèse 45 kilogrammes. Pour fabriquer chaque pièce, de la fibre de verre et de la fibre de carbone imprégnées de résine sont enroulées autour d'un cadre de moule en métal, puis durcies pour former des pièces hexagonales rigides.

La technique consiste à envelopper un composite avec un bras robotisé - conçu pour utiliser les propriétés matérielles de la fibre de carbone pour lui donner la même résistance que lors de la fabrication de pièces structurelles. Une série de ces modules individuels en forme de cellule sont utilisés pour créer la forme unique du pavillon. Chacune des 40 unités prend en moyenne trois heures à construire.

9. Le pavillon ICD/ITKE

Le professeur Achim Menges à Stuttgart a dévoilé une nouvelle architecture dans son nouveau pavillon ICD/ITKE, inspirée des méthodes de nidification des araignées aquatiques qui vivent sous l'eau et dans des cloques. Le pavillon est une coque légère en composite de fibres construite sur un film souple avec des fibres de carbone tissées robotiquement qui renforcent la structure, tout en utilisant le moins de matériau possible pour obtenir une stabilité structurelle.

10. Tomorrowland à Shanghai Disneyland

Couvrant une superficie de plus de 2300 mètres carrés, les vastes structures et sièges intérieurs et extérieurs du Shanghai Disneyland Daysun World sont composés de plusieurs centaines de revêtements adhésifs ignifuges (FR) avec des pièces moulées en composite FRP de différentes formes et tailles.