nouveau blog

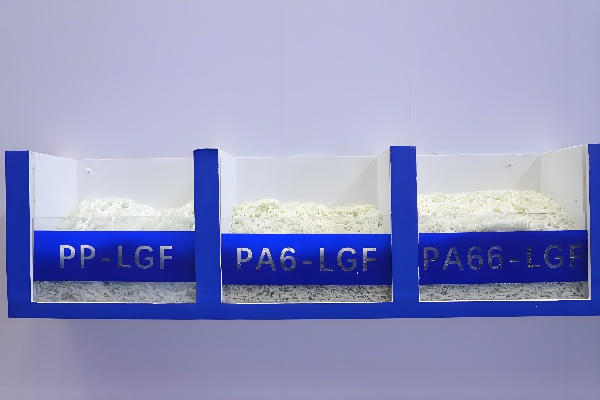

Avec le développement rapide de la industrie automobile , composites thermoplastiques renforcés de fibres de verre longues (LGF) ont été de plus en plus appliquées.

Dans le cadre de la tendance à l'allègement des véhicules automobiles, «

remplacer l'acier par du plastique

« est devenue une approche courante. En tirant pleinement parti des avantages de LGF,

faible coefficient de dilatation linéaire, résistance spécifique élevée, module spécifique élevé et excellente stabilité dimensionnelle

, son application dans les structures automobiles légères réduit efficacement le poids du véhicule, améliore les performances énergétiques et la maniabilité, réduit la consommation d'énergie et améliore l'autonomie de conduite.

Performance Analyse

1.1 Matériaux PP-LGF ignifuges

Matériaux en polypropylène renforcé de fibres de verre longues (PP-LGF)

Ils offrent d'excellentes propriétés mécaniques et une stabilité dimensionnelle, ce qui explique leur large utilisation dans divers secteurs industriels. Ils peuvent également être conçus pour présenter des performances ignifuges intumescentes ou synergiques. Ces matériaux sont principalement classés en deux types ignifuges :

à base d'azote et de phosphore

et

à base de brome

.

Le système azote-phosphore forme une couche de charbon poreuse et expansée à la surface de la matrice PP grâce à l'action des retardateurs de flamme. Cette couche agit comme une barrière thermique et anti-oxygène, améliorant la résistance mécanique et thermique du charbon, retardant efficacement la décomposition et l'oxydation de la résine matricielle et améliorant les performances ignifuges globales du système composite, assurant ainsi l'ignifugation de la résine matricielle.

Les retardateurs de flamme à base de brome exploitent principalement l'effet synergique brome-antimoine. Lors de la décomposition thermique, ils génèrent des substances inertes qui ralentissent ou interrompent la combustion. De plus, le HBr dense produit peut diluer l'oxygène de l'air ambiant, est ininflammable et peut former une couche protectrice à la surface du matériau pour inhiber la combustion, réduire la vitesse de combustion ou favoriser l'auto-extinction.

Le

propriétés

Les exemples de certains matériaux PP-LGF ignifuges typiques actuellement utilisés dans les applications sont résumés dans le tableau 1.

Tableau 1 Perfo

rmance des matériaux PP-LGF ignifuges

| Propriété |

PP‑LGF20 (azote‑phosphore) |

PP-LGF20 (à base de brome) |

|

Teneur en fibres de verre / % |

20 | 20 |

|

Résistance à la traction / MPa |

94,8 | 87,6 |

|

Résistance à la flexion / MPa |

149 | 132 |

|

Module de flexion / MPa |

5540 | 5620 |

|

Impact entaillé / kJ/m² |

20 | 17 |

|

Impact sans entaille / kJ/m² |

45 | 41 |

|

Ignifugation (3,2 mm) |

V-0 | V-0 |

D'après le tableau 1, on peut voir que les matériaux PP-LGF ignifuges, tout en conservant bonnes performances ignifuges synergiques , conservent également propriétés mécaniques considérables y compris la résistance à la traction, la résistance à la flexion et la résistance aux chocs entaillés.

1.2 Matériaux PA66-LGF

Matériaux PA66-LGF

sont des composites renforcés avec

haute résistance à la chaleur, haute résistance, module élevé et excellente ténacité

. Parmi eux,

PA66-LGF30

contient

Renfort en fibres de verre longues à 30 %

, tandis que le PA66-LGF25 en contient 25 %. Tous deux sont produits sous forme de granulés, ce qui améliore considérablement la résistance mécanique et la stabilité dimensionnelle du matériau, lui conférant une résistance exceptionnelle aux chocs.

propriétés

Les matériaux PA66-LGF typiques sont présentés dans le tableau 2.

Tableau 1 Perfo rmance des matériaux PP-LGF ignifuges

| Propriété | PA66-LGF30 |

PA66-LGF25 |

|

Teneur en fibres de verre / % |

30 | 25 |

|

Résistance à la traction / MPa |

170 | 151 |

|

Résistance à la flexion / MPa |

228 | 208 |

|

Module de flexion / MPa |

8050 | 7720 |

|

Impact entaillé / kJ/m² |

21 | 18 |

|

Impact sans entaille / kJ/m² |

69 | 66 |

Applications

Le LGF est largement utilisé dans automobiles, aérospatiale, sports, appareils électroménagers et emballage , avec le industrie automobile étant le principal secteur d'application, représentant environ 80% .

2.1 Roues automobiles

Nylon à fibres de verre longues (LGF)

est un

résistant aux hautes températures, autolubrifiant

Matériau renforcé capable de supporter des charges moyennes à élevées. Alliant parfaitement renforcement en fibres longues et lubrification, il peut fonctionner dans des conditions allant jusqu'à

130 °C

. Doté d'une bonne polyvalence, il convient aux applications de fonctionnement à sec, principalement utilisé dans les mouvements de rotation et de glissement, présentant une excellente résistance à la poussière et ne nécessitant aucun entretien.

Dans la conception et le développement de véhicules légers pour l'automobile, les matériaux PA66 renforcés de fibres de verre longues sont bien adaptés

composants de roues automobiles

, permettant la production de plaques composites et de roues de voitures particulières par moulage par injection.

La méthode de préparation des plaques composites consiste à sécher les granulés à 100 °C pendant 4 heures, puis à les mouler par injection. Les paramètres du procédé de moulage, tels que

La température et la pression de la vis, la pression d'injection, le temps d'injection, la contre-pression, le temps de refroidissement et la température du moule sont réglés en conséquence. Après moulage, les plaques sont refroidies à l'air libre jusqu'à température ambiante.

.

La préparation des roues composites suit un processus similaire :

Les granulés sont séchés à 100 °C pendant 4 heures, puis moulés par injection. Les paramètres du procédé comprennent la température des canaux chauds, la pression d'injection, le temps d'injection, la pression de maintien, le temps de maintien, le temps de refroidissement et la température du moule.

Le produit final est une roue composite de 15 pouces.

Des tests et analyses ultérieurs des plaques et des roues ont permis de déterminer la teneur en fibres de verre, leur longueur, leur orientation et leur répartition. Des essais de fatigue radiale sur les roues composites ont confirmé leur résistance à la fatigue.

2.2 Couvercle de capot moteur

Considérant la

résistance spécifique élevée, module spécifique et résistance aux chocs

en polypropylène renforcé de fibres de verre longues (PP-LGF), il peut être appliqué efficacement dans

composants de capot de moteur automobile

En optimisant la conception des moules et en ajustant les paramètres de traitement, des pièces répondant à la fois aux exigences d'apparence et de performance peuvent être fabriquées, répondant ainsi aux besoins des applications automobiles légères tout en minimisant les coûts.

Le PP-LGF30 a été sélectionné pour répondre aux exigences de performance des capots de moteur. Des essais de production et des vérifications de performance ont démontré que la résistance à la traction, le module de flexion, la résistance aux chocs entaillés et la température de fléchissement sous chaleur du matériau répondent aux exigences fonctionnelles des capots de moteur. Pour optimiser encore l'aspect visuel des pièces en PP-LGF30, des ajustements dans la conception et la fabrication des moules sont nécessaires. Par exemple :

des trous d'aération peuvent être ajoutés aux extrémités d'écoulement de la matière fondue pour résoudre les difficultés de moulage, et un contrôleur de température du moule peut être utilisé pour maintenir la température du moule à 80 °C

.

2.3 Module frontal

Dans le développement de la conception légère des automobiles, le polypropylène renforcé de fibres de verre longues (PP-LGF), avec ses

excellentes propriétés mécaniques

, peut être appliqué à

cadres avant d'automobile

En intégrant raisonnablement l'optimisation de la topologie structurelle, l'optimisation dimensionnelle et d'autres techniques de conception, et sur la base du développement de matériaux PP-LGF modifiés, des formulations optimisées et une sélection de matières premières peuvent être obtenues, suivies d'un compoundage expérimental, de tests et d'une conception de processus.

2.4 Capot avant

Dans le processus de conception de véhicules légers pour automobiles, le concept de «

remplacer l'acier par du plastique

» est de plus en plus reconnue. Le capot avant des véhicules est désormais fabriqué en utilisant

composites plastiques renforcés de fibres de verre longues

, qui sont

plus léger

en poids et en offre

performances supérieures

, réduisant ainsi efficacement la masse globale du véhicule et répondant aux exigences d'économie d'énergie et de réduction des émissions.

Lors de l'amélioration et de l'optimisation de la structure du capot avant, des composites renforcés de fibres de verre longues ont été utilisés en remplacement des matériaux métalliques d'origine. Sur la base des propriétés mécaniques de ces composites, une méthode de conception équivalente a été appliquée pour repenser la structure du capot, en tenant pleinement compte de facteurs tels que le module d'élasticité, le coefficient de Poisson et l'épaisseur des parois minces afin de déterminer l'épaisseur initiale du capot.

D'autres optimisations structurelles incluent :

conception de plates-formes encastrées et de nervures transversales dans le panneau intérieur comme structures de renforcement ; ajout de petits trous sur le bord inférieur du panneau intérieur ; adoption de méthodes d'assemblage à haute adhérence pour l'assemblage du capot ; et simplification de la structure sectionnelle des côtés du capot en utilisant des joints latéraux adhésifs

.

2.5 Squelette du tableau de bord

Comme tout le monde

léger et très résistant

matériau plastique composite, le polypropylène renforcé de fibres de verre longues (PP-LGF) peut être appliqué dans le

squelette du tableau de bord automobile

. Tirant parti de ses excellentes propriétés mécaniques et de sa bonne adaptabilité environnementale, le PP-LGF est produit par imprégnation à l'état fondu, ce qui le rend idéal pour les composants structurels hautes performances tels que les tableaux de bord. Le tableau de bord est un élément essentiel de l'habitacle, exigeant une résistance et une rigidité élevées.

2.6 Bac à piles

Les composites renforcés de fibres de verre longues peuvent être fabriqués en

composants de forme complexe

par moulage par injection. Pour répondre aux exigences d'allègement des bacs de batteries automobiles,

PP-LGF40

Ce matériau a été sélectionné pour ses performances supérieures en matière de réduction des vibrations et du bruit du véhicule, ainsi que pour sa résistance accrue à la corrosion. Il peut être moulé en pièces aux structures complexes et aux parois fines, et des nervures structurelles sont intégrées à la conception pour améliorer la rigidité. Lors de la production, les transitions d'angle doivent être chanfreinées afin de réduire la concentration des contraintes et d'assurer la rigidité requise du bac de batterie.

Les trous de montage et les brides latérales étant soumis à des contraintes plus élevées que dans d'autres zones, il est nécessaire d'augmenter l'épaisseur des parois des trous de montage et de renforcer ces zones par des nervures s'étendant jusqu'à la surface du plateau. Pour renforcer encore la rigidité des parois latérales du plateau, une bride de 2 mm doit être ajoutée sur les côtés et le périmètre, et une structure nervurée en forme de grille (en forme de « 井 ») doit être placée à l'arrière du plateau. De plus, des ajustements de pré-déformation doivent être effectués pour tenir compte du gauchissement induit par les nervures, garantissant ainsi la compatibilité de l'assemblage et une rigidité accrue, répondant ainsi aux exigences d'allègement automobile.

2.7 Hayon

Les hayons en plastique peuvent être fabriqués à partir de composites thermoplastiques en polypropylène renforcé de fibres de verre longues (PP-LGF), qui offrent

faible densité, haute résistance, haute recyclabilité et flexibilité de conception

Ce matériau réduit considérablement la consommation de carburant et les émissions de CO₂ tout en permettant une meilleure intégration des composants. Dans la conception du hayon en PP-LGF, les panneaux intérieur et extérieur sont fabriqués par moulage par injection, avec collage entre eux. Une analyse de simulation est réalisée pour optimiser l'intégrité structurelle et les performances.

Le panneau intérieur, qui supporte la majeure partie de la charge, doit être renforcé par des nervures en partie supérieure et au niveau des montants D afin de garantir une résistance et une rigidité suffisantes. Lors du choix des matériaux, les coefficients de dilatation thermique linéaire des panneaux intérieur et extérieur doivent être soigneusement adaptés, notamment en cas d'alternance de températures chaudes et froides. Une mauvaise adaptation peut entraîner un décollement ou une déformation des joints adhésifs sous l'effet de la dilatation et de la contraction thermiques.

2.8 Fender

Grâce à un équipement de moulage spécialisé, des granulés de PP-LGF, contenant une teneur en fibres de verre spécifique, sont préparés et appliqués dans les structures d'ailes automobiles. Lors de la conception d'ailes en PP-LGF, il est essentiel d'évaluer l'influence de la teneur en fibres de verre sur

propriétés de traction, de flexion et d'impact

grâce à des tests de performance.

Les propriétés non mécaniques doivent également être évaluées, notamment la résistance aux températures élevées, aux cycles thermiques, aux chocs, à la chaleur humide, à l'eau et aux solvants. Des observations doivent être effectuées pour détecter d'éventuels défauts tels que déformation, fissuration, farinage, formation de bulles, adhérence ou dissolution. Après les essais, les composants du garde-boue sont assemblés afin de valider leur adéquation à différentes conditions d'utilisation et de garantir leur conformité aux exigences de légèreté et de durabilité.

Conclusion

En résumé, les composites renforcés de fibres de verre longues sont des matériaux légers et hautement résistants. Dans le contexte du remplacement de l'acier par le plastique, ils présentent des avantages de performance indéniables et sont parfaitement adaptés à la conception de structures automobiles légères.